MiniFAB Services

Transforming Ideas into Fully Manufactured Products

Overview

MiniFAB's experienced team manages complex projects with rapid translation of design concepts into working prototypes and small or large-scale manufacturing in an ISO 13485 certified process. A flexible staged development plan allows our clients to engage at any point in their product development cycle.

MiniFAB demonstrates and proves design concepts faster so you can accelerate product commercialisation. Continuous progress monitoring assesses and manages risk while optimising requirements to meet changing business needs and technical milestones. Our design-for-manufacture approach ensures your products can transition from prototype to high volumes simply and at low cost.

Integration – The Heart of What We Do

At an organisational level, this refers to our ability to form a multifaceted team, utilise the right technical capabilities and employ our project management skills to develop the product.

At an engineering level, it is our ability to understand the mechanical, electrical, optical, software and biochemical requirements of complex systems, and then to implement micro, nano and biotechnology solutions in the most appropriate manner.

At a technical level, it is our ability to bring together numerous sophisticated technologies, techniques and methods in a single device.

Continue reading about our Technology and Process

Product Development – Design & Prototype

You may have a concept and need to determine the best approach; you may have drawings and require rigorous design review; or you may have finalised your design and need a partner to manufacture prototypes or products. Our team of engineers and industrial designers can work seamlessly with your team and your needs.

Reading more about MiniFAB's Design and Prototype services.

Contract OEM & ODM Manufacturing

MiniFAB thrives on solving the challenges raised by your needs. We specialise in volume manufacturing of disposable microfluidic cartridges, with capabilities that are readily transferrable to any number of devices, components and systems.

We have an extensive collection of fabrication equipment with dedicated facilities for packaging and assembly, test and characterisation, production and development. We provide manufacture of products all under one roof.

Our flexible engagement model means that you can develop a few prototypes with us, have us perform volume manufacturing of your product, or leverage our expertise to set up and transfer manufacturing.

Find out how MiniFAB can cost-effectively Manufacture and Assemble your product.

ISO 13485 & GMP quality systems

MiniFAB can offer full-scale, ISO-certified volume manufacturing from our 45,000 ft2 (4,200 m2) facility that includes 4,000ft2 cleanrooms (built to ISO 7 / Class 10,000). Our business incorporates ISO 9001, ISO 13485:2003 and GMP quality systems to provide traceability and relevant levels of control. Data from our Quality Management System (QMS) is instrumental in ensuring the highest standards in manufacturing.

Technology and Processes

Our Expertise in Solving Your Toughest Problems

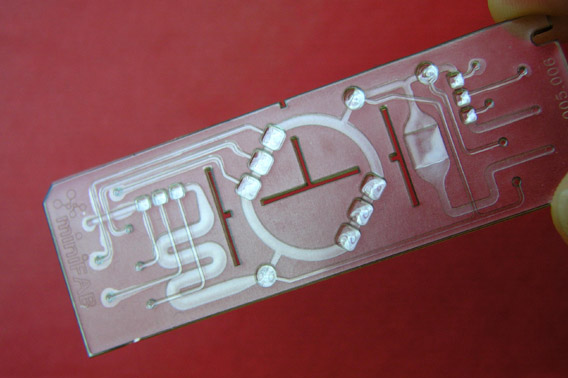

MiniFAB specialises in precision engineered polymer microfluidic devices, and can generate microfeatures with exceptional tolerances. MiniFAB has specific expertise in the design and manufacture of challenging combinations of micro and macro features. With our track record of successfully solving manufacturing problems that "couldn't be solved," we are so much more than a job shop — we generate solutions for your technical challenges.

MiniFAB has a wide selection of specialised and state-of-the-art equipment installed in cleanrooms built to Class 10,000 (ISO 7) that enable us to provide a unique and comprehensive service. MiniFAB also has a bio lab (PC2) so that we can perform side by side testing with our clients and provide a robust verification system.

Hybrid Integration & System Integration

MiniFAB expertly integrates different functionalities, materials and process to create customised solutions for your applications.

Reagents on Cartridge

- On-cartridge blisters

- On-cartridge reservoirs, pouches

- Rehydration of dried/lyophilised reagents

- Activation systems

Electrode Integration

- Integration of planar electrodes onto polymer

- In-channel electrodes

- Die-bonded chips

Fluidic Metering

- Accurate and repeatable

- On-cartridge metering features

- Instrument controlled metering

Multilayer Cartridges

- Integration of multilayers and components

- Rigid and flexible layers

- Carrier and interposer layers for hybrid integration

- 2D and 3D fluidic networks

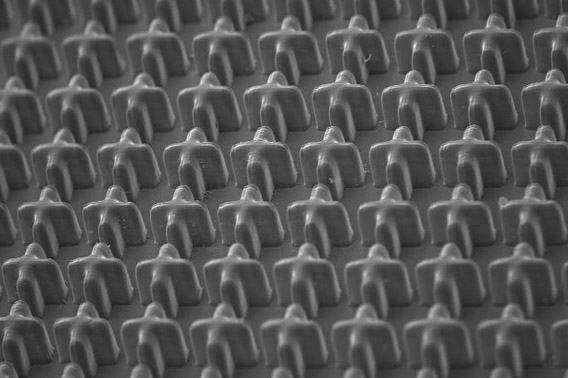

Micro-features

- Reliable manufacturing of complex, precise in-channel micro-features with high aspect ratios

- Micro-holes, shapes, textures

- Micro-optical structures

Integrated Filters

- Hydrophilic / Hydrophobic membranes

- Separation membranes

- Filter membranes

- Micro-mechanical / patterned foils

Valving

- Passive valves

- Active valves

- Burst valves

- Flap / membrane valves

- Commercial (off-the-shelf) valve integration

Mixing

- Highly effective on-cartridge mixing structures

- Rapid mixing over small areas

- 2D and 3D structures

- Integrated microfeatures (e.g. herringbones)

Biosensor Integration

- Optical detection chambers

- Electrochemical biosensors

- Silicon biosensors

- MEMS

- Nanobiosensors

MiniFAB's Process Capabilites and Techniques for Product Design and Manufacture

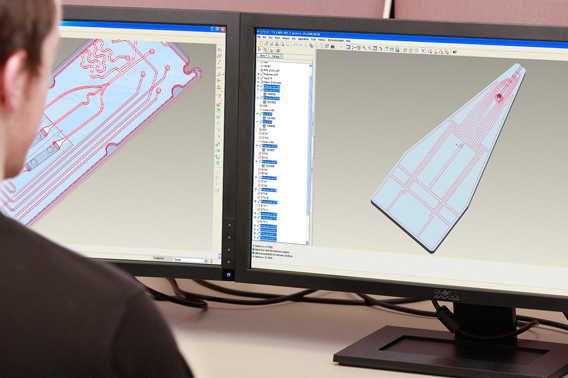

Design

- Concept Generation

- Computer Aided Design (CAD)

- Design for Manufacture

- Failure Mode and Effects Analysis (FMEA)

- Risk Analysis

- Industrial Design and Human Factors Analysis

Proof-of-Concept

- Micro Milling

- Excimer Laser

- Carbon Dioxide (CO2) Laser

- Photolithography

- Bonding and Lamination

Replication

- Electroform Tooling

- Hot Embossing

- Nano Imprint Lithography (NIL)

- Casting

- Injection Molding

Assembly

- Lamination

- Thermal Diffusion

- Ultrasonic Bonding

- Adhesive Bonding

- Solvent Bonding

- Wire Bonding

Packaging

- Hybrid Packaging

- Polymer Packages

- Blister Reagent Storage

- Surface Modification

- Fluidic Connectors

- Optical Windows

Testing

- Optical Microscopy

- Scaning Electron Microscopy (SEM)

- Laser Scanning Confocal Microscopy

- Surface Roughness Measurement

- Fluidic Testing

- Biological Testing

Microengineering & Materials

- Polymers including PC, PMMA, ABS, PVC, PET, COC, COP, PI, PEEK, PP, PU, PS and others

- Thin film deposition by magnetron sputtering of Al, Cu, Au, Cr, Ti, Ni, W and other metals

- Conformal parylene coatings for biocompatibility, chemical resistance and environmental applications

- 4" silicon wafers with SU-8, AZ, or BPR photoresist or laminar dry film resists

- Electroformed thick films in nickel, copper or alloys

- Hybrid solutions that combine polymer, metal, ceramics, PCBs and composites

Manufacturable Microfeatures

- Ports with variable geometries and sidewall angles

- Features of varying depths, aspect ratios and geometries with either a positive or negative profile

- Channels and grooves with controlled sidewall profiles and interconnectivity

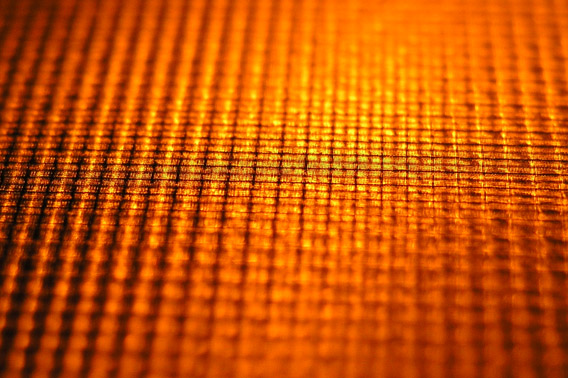

- Textures with many pattern geometries to modify tactile, optical, fluidic or mechanical properties

- Optical structures for diffractive and refractive effects

Microtooling and Replication

MiniFAB produces microfeatured parts used for tooling as well as final products. MiniFAB has extensive experience in combining polymer, metal, and injection molded tooling that incorporate micro and macro-features, including:

- Polymer tools for low-temperature replication processes and low-volume manufacturing

- Electroformed metal tools for higher temperature replication processes and low- to medium-volume manufacturing

- Tools for injection molding suitable for high-volume manufacturing

MiniFAB's approach to microfabrication is aimed at reducing development and manufacturing costs by removing the need to use expensive prototyping processes at the earliest practical point. In so far as practical, MiniFAB uses materials in the prototyping processes that are the same as those used in volume manufacture.

Design & Prototype

Design for Manufacture

MiniFAB has exceptional in-house design and engineering competence, tackling some of the most difficult problems to create solutions that provide value for our clients through the unique combination of technologies, processes, and expertise.

MiniFAB's Product Development Team leverages our Microfluidic ToolBox to design diagnostics, instruments, medical devices, microfluidic components and complete systems. The Microfluidic ToolBox is used to make informed decisions about the interface between non-disposable instruments and disposable cartridges, generating insight into strategic decisions for the location of critical structures like pumps, valves, heaters, reagent storage and waste reservoirs. When combined with 3D concepts for your disposable cartridge, MiniFAB's Microfluidic ToolBox brings your product vision to life sooner.

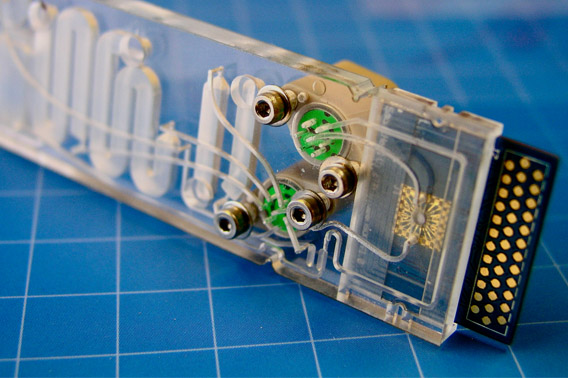

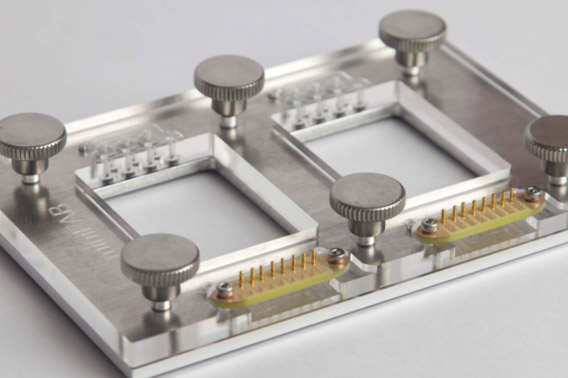

System Interfaces & Fluid Control

One of the most critical product development challenges involves interface design between the cartridge and the fluid control system. MiniFAB has developed simple systems for this interfacing, including manifolds to connect fluidic cartridges for sample and reagent introduction, and handling of air and waste. Integrated features for mixing, reservoirs, valves, channels and flow cells enable flow regulation and control, giving each cartridge the functionality required to perform a specific task.

Prototyping

MiniFAB provides prototypes for testing and validation of design as well as small volume production runs. For initial performance testing, MiniFAB has created a microfluidic development platform – the MiniCHEMLAB. The MiniCHEMLAB enables rapid drop-in performance testing and may be easily customised to include sensors, heaters and any other components required by our clients. MiniCHEMLAB cartridges produced during early development stages enable functionality testing and rapid modification to optimise processes in the work flow. MiniCHEMLAB is available for rent or purchase during development programs.

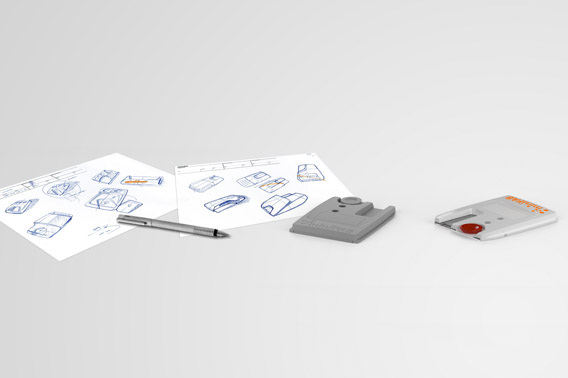

Industrial Design

MiniFAB engages and integrates its industrial design team throughout the product development process, from concept generation through manufacture, to bridge the gap between innovative engineering and human interaction, ensuring all aspects of both the product and manufacturing solution address the needs and desires of the user.

With an ever-watchful eye on market and consumer trends, in spaces beyond those of microfludicis and medical diagnostics, MiniFAB’s designers add value to products through ergonomics, visual styling, manufacturing conceptualisation and material exploration to create highly desirable, competitive and usable products.

MiniFAB offers a wide range of creative services, from concept generation, ideation and visualisation, through to physical prototyping and design assessment. Rapid application of industrial design, through sketching and digital visualisation, brings innovative ideas and solutions surrounding the use, aesthetics and graphics of a product early in the design phase, establishing a solid visual and functional direction that is evolved throughout the project.

Our capabilities in industrial design include:

- Brainstorming

- Concept generation

- Digital visualisation

- Ergonomic and use case investigations

- 3D prototypes / study models

- Brand identity

- Aesthetic development

- Design assessment

Manufacture & Assembly

From Concept to Manufactured Product

MiniFAB is a development and manufacturing company specialising in disposable polymer microfluidic cartridges. With ISO 13485-certified manufacturing processes, MiniFAB can manufacture your new or existing products rapidly and reliably with extremely high tolerances achieved through integrated engineering and manufacturing. At each stage of development, MiniFAB can assist with all regulatory aspects of medical devices and components.

Process Development

One of our key strengths is the ability to provide novel processing solutions for products where conventional manufacturers or manufacturing processes are unsuitable. The challenges that we regularly address include the inclusion of micro-sized features, the combination of micro and macro features, combinations of process steps, challenging assembly steps, stringent QC requirements and packaging of the final product.

Manufacturing Volume

MiniFAB's flexible ISO9001 manufacturing capacity is tailored to the needs of each of our clients, regardless of production volume. Our trained operators deliver small and large volumes of high quality products to clients around the world.

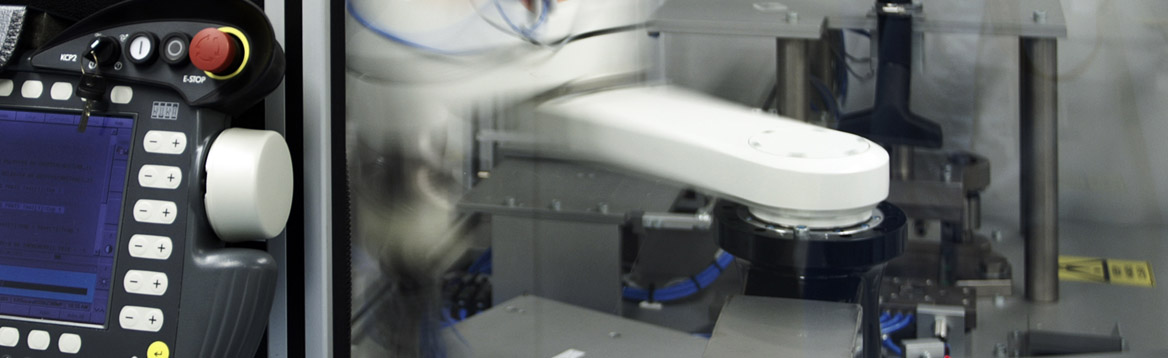

Automation Processes

The automation of production processes is essential to achieve large production capacities and a cost effective production environment. MiniFAB's team of experienced process engineers have a proven track record of establishing automated, specialised production processes for the manufacturing of highly toleranced, low cost disposable products.

Assembly & Packaging

Highly-qualified technicians assemble products in a quality controlled environment. MiniFAB's packaging engineering expertise can assist you to efficiently manage the specification and implementation of a packaging solution to your requirements.

Supply Chain Management & Logistics

MiniFAB manages a comprehensive supply chain covering everything from advanced and often unique engineering materials, consumables and spare parts, equipment and components, and custom services. Working closely with clients, MiniFAB develops rigorous shipping processes to deliver products internationally, including cold-chain management. We can deliver all aspects of the supply chain and logistics for your product.

Manufacturing Transfer

MiniFAB's strict adherence to Design for Manufacturing principles during the development phase of your product ensures a smooth transition from concept design to manufacturing. MiniFAB's Transfer to Manufacturing program is designed to transfer the finished product to an ISO13485 compliant manufacturing system. Pilot line manufacturing can be established at MiniFAB utilising our infrastructure. Additionally, MiniFAB can transition manufacturing to a location of your choice.